Trash for the sake of science?

Science is unsustainable. But can I make a difference?

By: Maria Elisa Almeida Goes, Allison Lewis, and Bhargavi Murthy

Graphics: Nina Lautenschlaeger

Introduction

Germany leads global recycling rankings with up to two thirds of all municipal waste being recycled. However, research institutions within the Max Planck Society (MPS) do not appear to reflect this enthusiasm towards recycling. In the absence of a central sustainable directive from headquarters, institutes seem to implement whichever policies they feel inclined to, and often have little or no recycling initiatives. Research labs consume enormous amounts of energy and generate substantial non-recyclable and toxic waste. They can consume three to six times more energy than commercial buildings, mostly due to refrigeration and ventilation systems. Lab experiments also rely heavily on single-use plastics and personal protective equipment (PPE). A letter published in Nature, by the University of Exeter, estimated that 280 bench scientists in the university’s bioscience department generated 267 tonnes of plastic in 2014 alone.

Reducing the environmental impact of science requires both individual and collective effort. Even if your institute has energy efficient equipment and takes part in waste recycling programs, the successful execution of sustainability goals lies in your hands. It can also be the other way around; some PIs or institutes may not have the time, resources, or even interest, in adopting sustainable practices. In this case, it is up to the eco-conscious individuals to take the first steps towards practicing sustainability and educating their peers; practice before you preach.

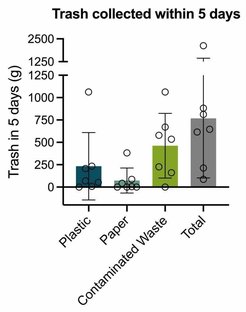

One of the greatest barriers to practicing sustainably is knowing where to begin. This highlights the importance of a sustainability assessment to identify our biggest contributors to waste; then we can implement alternatives and establish parameters to measure the effectiveness of our changes. Ideally, an assessment would take place at the institutional level, with input from all relevant employees, transcending what individuals can achieve piecemeal. Until top-down initiatives are fully realized it remains the responsibility of the environmentally conscious to be the drivers of change. In this spirit we embarked on our own sustainability assessment in the form of a “lab waste challenge”, to analyze qualitative and quantitative aspects of the waste produced over a week (5 weekdays). We diligently sorted and weighed consumables, personal protective equipment, and packaging materials. Six participants in the waste challenge were bench scientists/technicians from biological laboratories and one was from an administrative office.

Results

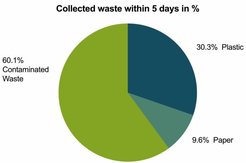

Plastic materials - packaged in more plastic and paper - were one of the biggest contributors to waste. In just one week, 7 participants accumulated 5.5 kg of waste: 1.7 kg was clean plastic and 0.5kg clean paper. This demonstrates that at least 39% of waste could be easily recycled, if such initiative exists. To illuminate the sheer scale of the waste problem we extrapolated these numbers to a period of one year. We estimate that a single researcher per year would generate roughly 14 kg of recyclable waste and a whopping 22 kg of non-recyclable waste. The non-recyclable waste is typically a mixture of different materials - possibly contaminated with hazardous substances - like plastic tubes, pipettes and personal protective equipment (PPE) . But it's not all doom and gloom. Once armed with the results of our sustainability assessments, we attempted to identify if and where sustainable alternatives exist.

Alternatives-PPE

From our waste challenge, PPE represented nearly 37% of non-recyclable plastic waste, mostly attributed to our reliance on gloves. Gloves are a sensitive topic; due to biosafety reasons, gloves must be immediately discarded after use. TerraCycle, however, is an interesting venture that employs innovative technologies to recycle almost any type of non-recyclable waste from households, commercial buildings or research facilities. The KIMTECH ™ nitrile disposable glove recycling program, in collaboration with Terracycle, can upcycle gloves into reusable products like transport boxes or park benches, instead of the standard practice of sending gloves to landfill.

Disposable plastic shoe covers and hair bonnets could be easily swapped for sterilizable shoes and washable fabric bonnets. But despite the availability of sustainable alternatives, many scientists cannot make the switch due to a lack of supporting institutional policies. For example, they may face bureaucratic issues if they wish to order sustainable alternatives which are outside the current supply contracts of the MPS.

Alternatives- Potentially contaminated plastic

Major contributors to non-recyclable waste were plastic consumables, like pipettes, tubes, and cell culture dishes, which accounted for roughly 62% of plastic waste. Similar to gloves, there are few existing alternatives on this front. But trying to strike a balance between performing quality research while also being mindful of the subsequent environmental impact can be challenging - especially given the lack of a sustainability-oriented mindset within the MPS. Fortunately, there are glass alternatives to address the use of plastic serological pipets, falcon tubes, and slides. The switch to sterilizable glassware could result in a shocking 29% reduction in non-recyclable contaminated plastic. But, most autoclaved glassware is wrapped in aluminium foil, which instead of being reused or recycled, is simply thrown away in the same bin as non-recyclables. Increasing and diversifying the supply of glassware to laboratories could be an achievable goal, for both, scientists and the research institutes.

Alternatives-clean plastic

The ubiquity of plastic packaging we deal with in our personal lives, unfortunately, also extends to the lab environment. Although we can't control how companies package their products, we can reduce our reliance on pre-filled, single-use tip boxes. Certain types of clean plastics are recyclable (to an extent) when correctly sorted. For instance, at the UAB Green Lab program, labs are sending pipette tip boxes to a local recycler and are also able to recycle styrofoam and various types of plastics (type 1,2,4,5). In a recent publication by researchers at Rice University, clean plastic waste, such as tip boxes, could possibly be converted to high-quality graphene by a method called Flash Joule Heating; graphene has numerous applications due to its strength, elasticity and good conductivity of heat and electricity.

Conclusion

From our small-scale lab waste challenge, we identified that about 39% of the waste produced by bench scientists had recycling potential, characterized by clean plastics like pipette-tip boxes and single-use packaging. Of the remaining majority of non-recyclable waste, gloves alone accounted for 25%. We also observed that almost 30% of the non-recyclable “potentially contaminated” waste made of plastics, could be replaced by alternatives, such as glass pipettes, reusable tubes and reusable shoes.

The first step towards reducing waste isn’t the three R’s - reduce, reuse and recycle. There is another R above all, the most effective: Refuse. The first step is moulding our mindset to refuse an unsustainable product or practice. For instance, instead of labeling contaminated waste as “unavoidable”, a shift in perspective can allow one to plan experiments in advance to minimize resources. It is, however, true, that sustainable alternatives do not yet exist for all applications. Reusing is the best step in this scenario, like using washable PPE. Though recycling is the next option after reuse, we often forget the energy costs associated with it. Segregating plastics, melting them down and repurposing them is challenging, laborious, and thus, more expensive than producing new plastic.

Apart from the waste problem, the energy consumed by research facilities leaves a massive carbon footprint and a significant proportion of public research funding is spent on our labs’ energy costs. Taking simple steps – like increasing the freezer temperature from –80°C to –70°C, installing LED bulbs and turning off fume chambers or cell culture hoods – can significantly reduce energy consumption, a few tonnes of carbon emissions, and of course, the annual electricity bill.

Being sustainable requires a paradigm shift in our mindset, in every aspect of our life, because trying to live circularly in a linear economy is like trying to fit a circle in a square. Remember that you cannot be perfectly zero-waste or zero-carbon: you can only strive for it. Every little effort is better than not trying at all and regular practice can make sustainability a habit.